- WEBSITE -

Current location: HOME > NEWS > Frequently Asked Questions >

Analyze the technical upgrade of light steel keel forming machine.

Time:2025-12-29 11:01:29 Author:xiangyi Click:166

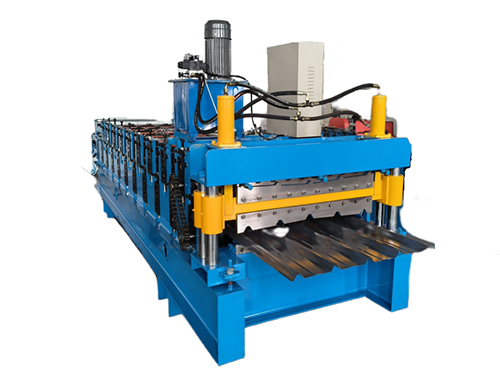

With the deep transformation of the construction industry towards industrial assembly, intelligent manufacturing and green and low carbon, the light steel keel forming machine, as the core equipment of light steel building materials processing, is undergoing all-round technological innovation. Its upgrade trajectory focuses on key areas such as precision control, productivity enhancement, intelligent integration and low-carbon energy saving, which accurately matches the production demands of modern prefabricated buildings in scale and standardization. The following will be a deep dismantling of its core technology upgrade context:

First, the innovation of intelligent control system: from extensive control to precise empowerment

Iterative upgrading of numerical control core: get rid of the extensive control mode of traditional relay, and upgrade to a precise control system with PLC programmable logic controller and servo drive, so as to realize millisecond-level precise regulation and control of core process parameters such as roll speed, screw down stroke and cutting length. After optimization, the molding thickness error can be strictly controlled within ±0.1mm, the cutting accuracy reaches the high standard of 1 mm, and the consistency of product specifications is greatly improved. What's more noteworthy is that the high-end models have added the function of process parameter memory and quick retrieval, which reduces the time for mold changing and debugging of different specifications of keels by 70%, and it only takes 5 minutes to complete the production mode switching, greatly improving the flexibility of multi-category production.

Integration of Internet of Things and remote operation and maintenance: By embedding multi-dimensional sensors and Internet of Things modules, the equipment can collect key operation data such as roller working temperature, motor running speed and hydraulic system pressure in real time, and upload them to the cloud management platform through 5G or industrial Ethernet. Users can remotely monitor the running status of equipment in real time with the help of mobile terminals or computers, and the system can realize fault prediction and early warning based on data modeling, effectively reducing the unplanned downtime and making the comprehensive utilization rate of equipment exceed 92%. In addition, the system can realize data interoperability and collaborative linkage with upstream and downstream production links, laying a solid foundation for building a whole-process unmanned production line.

Second, optimization of molding process and upgrading of core components: laying a solid foundation for efficient production.

Multi-pass progressive cold bending technology is dominant: the progressive cold bending forming technology with multiple sets of rollers (typically 12 sets) is popularized and applied, so that the metal raw materials bear uniform step-by-step shaping force during processing, and the defects such as keel cracking and warping caused by local stress concentration are avoided fundamentally. The strength and toughness of the keel processed by this process are significantly enhanced, which can meet the engineering design requirements of bending strength above 345MPa and meet the structural requirements of high-grade buildings.

The material and machining accuracy of core components are improved: the key load-bearing components such as frames and rollers are made of high-strength alloy steel. After precision forging, quenching and tempering heat treatment and chrome-plated surface hardening treatment, the structural rigidity and wear resistance of the components are greatly improved, and the service life of the equipment is prolonged by more than 50%. Among them, the control of roller surface roughness reaches a higher standard, which not only reduces the scratch on the surface of raw materials during processing, but also ensures the long-term stability of molding size and reduces the risk of product defects and equipment failure caused by component wear.

Integrated design of the whole process: innovatively integrate the four core processes of uncoiling, leveling, forming and cutting to create an integrated production line. Compared with the traditional decentralized equipment, the floor space is reduced by 60%, which realizes seamless continuous processing from the raw materials of coiled materials to the finished keel, completely breaks the connection barrier between each working procedure, and improves the production fluency and site utilization rate simultaneously.

Third, automation upgrade and capacity breakthrough: unlocking the new efficiency of large-scale production

The whole process of unmanned transformation and landing: from the traditional manual operation of single machine group to the fully closed-loop automatic production line, the whole process of automatic feeding of raw materials, precise forming, cutting to length and automatic palletizing of finished products has been realized. The manpower demand of a single production line has been sharply reduced from five to two, the labor cost has been reduced by 60%, and the production capacity of a single shift can reach 5000 meters stably, effectively matching the large-scale supply demand of large-scale assembled construction projects.

Leap-forward improvement of molding speed: by optimizing the transmission system architecture, adopting high-precision hard-toothed gears and precision bearings, and matching with high-efficiency power units, the molding speed of equipment can be improved breakthrough. The molding speed of the new generation model can reach 30-35 m/min, which is more than 40% higher than that of the traditional equipment. At the same time, the optimized transmission system runs more smoothly, the working noise is significantly reduced, and the energy loss is accurately controlled while improving efficiency.

Fourth, multi-functional integration and customized upgrade: to meet the needs of diversified buildings

Modular design to realize multi-purpose of one machine: by adopting modular core structure and quickly changing roller dies, light steel keels with various cross-sections such as U-shaped, C-shaped and L-shaped can be flexibly produced, covering mainstream specifications such as 50 series, 75 series and 100 series. At the same time, it supports customized processing of special-shaped keels, such as special shapes such as arc and wave, and the minimum bending radius can be controlled at 50mm, which successfully meets the decoration and structural requirements of special buildings such as theaters, airports and convention centers.

The range of processing specifications has been greatly expanded: the thickness range of the processed raw materials of the upgraded equipment has been expanded to 0.3-3mm, and the width has been covered by 30-300mm, which fully covers the specification requirements of light steel keel in different scenes such as civil buildings and industrial workshops. In addition, according to the building codes of different regions and the special demands of customers, the production equipment with exclusive specifications can be customized to enhance the market adaptability.

Fifth. Low-carbon energy-saving transformation and safety protection strengthening: practicing the concept of green and safe production

Comprehensive application of energy-saving technology: equipped with a new generation of servo hydraulic system, the power transmission path is optimized, the energy conversion efficiency is improved, and the energy consumption per unit capacity is reduced by 20%-25% compared with the previous generation equipment, which deeply meets the green production requirements under the "double carbon" strategy. Some high-end models have also upgraded the cooling and lubrication system, and added waste liquid recovery and recycling devices to reduce pollutant emissions and achieve a win-win situation for environmental protection and benefits.

Construction of full-dimensional safety protection system: Add multiple intelligent protection devices such as overload protection, intelligent detection of material breakage and emergency stop linkage, which can quickly trigger automatic stop and alarm mechanism when the equipment is in abnormal operation state, effectively avoiding equipment damage and production safety accidents. At the same time, totally enclosed protective covers are installed for high-speed rotating parts such as rollers and transmission chains, and the electrical system adopts reliable grounding design, which fully meets the general technical standards for mechanical and electrical safety (GB 5226.1-2019).

On the whole, the technological upgrading of light steel keel molding machine has always been promoted around the five core directions of "accuracy, efficiency, intelligence, diversification and greening". This iteration not only achieved a double leap in production efficiency and product quality, but also effectively reduced labor costs and energy consumption, provided solid equipment support for the industrial transformation of the construction industry, and promoted the light steel building materials processing industry to a new stage of high-quality development.