- WEBSITE -

Current location: HOME > NEWS > Frequently Asked Questions >

Brief introduction to the use method of steel plate leveler

Time:2025-12-29 10:48:19 Author:xiangyi Click:81

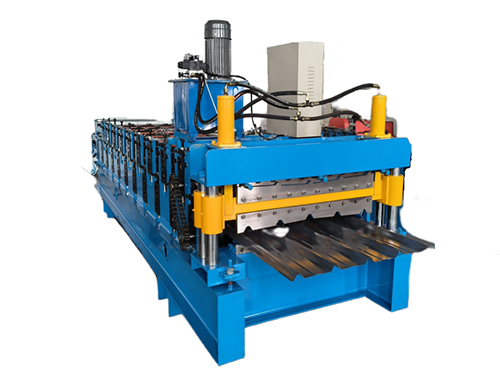

The core function of the steel plate leveler is to correct the plane error of the steel plate and release the internal stress of the material, and the operation process must strictly abide by the safety criteria and standard procedures. The key steps are summarized as follows:

First, preparation before operation

Equipment pre-inspection: carefully check whether there are scratches and attachments on the surface of leveling roller, whether the transmission mechanism and hydraulic system (hydraulic model) run smoothly, and whether all kinds of safety protection components are in good condition.

Parameter adaptation: according to the thickness, material characteristics and width of the steel plate to be processed, the spacing, running speed and reduction of leveling rollers are accurately adjusted. Usually, it is necessary to control the reduction of thin steel plate and slow down the roll speed; Thick steel plates or high-strength steel plates need to increase the reduction strength moderately.

Workpiece cleaning: thoroughly remove impurities such as rust, oil stain and welding slag on the steel plate surface to avoid scratching the roller surface or affecting the straightening accuracy during leveling.

Second, the feeding process operation

Idle commissioning of equipment: start the equipment for no-load operation, and then enter the next step after confirming that the roller system is turning correctly and there is no abnormal noise.

Smooth feeding: With the help of crane, vacuum sucker or manual assistance, push the steel plate smoothly into the feed inlet of the leveler to ensure that the steel plate is perpendicular to the central axis of the roller system to prevent deviation.

Special workpiece assistance: for steel plates with super-long and super-wide specifications, it is necessary to match with an auxiliary feeding device to avoid the end of the steel plate from warping or bending damage.

Third, leveling operation implementation

Real-time monitoring operation: after the steel plate enters the roll system, closely observe its running state. If deviation is found, adjust the feeding guide mechanism immediately to correct it.

Parameter fine adjustment and optimization: After the leveling of the first steel plate is completed, stop the machine to test its flatness, and fine-tune the roll gap or reduction in several times according to the test results (following the principle of "small amplitude and multiple adjustments") until it reaches the qualified standard.

Specification for batch operation: During batch leveling, keep uniform feeding, reduce frequent start and stop of equipment, and regularly check the flatness of steel plate to avoid unstable product quality caused by parameter deviation.

Fourth, unloading and subsequent treatment

Smooth receiving: when the leveled steel plate is sent out from the discharge port, the receiving device is used to receive it smoothly to prevent the steel plate from falling and causing deformation.

Quality inspection: the flatness of the leveled steel plate shall be rechecked, and the unqualified products shall be corrected again after readjusting the parameters.

Finishing work: after the operation, turn off the power supply of the equipment, clean up the waste and sundries around the roller system and equipment, and fill in the equipment maintenance record completely.

Core safety instructions

Protective gloves, helmets and other protective articles must be worn during operation, and it is forbidden to put hands or other parts of the body into the gap of the roller system.

It is forbidden to adjust various parameters during the operation of the equipment, and it is forbidden to overload the steel plate beyond the rated specifications of the equipment.