- WEBSITE -

Current location: HOME > NEWS > Company News >

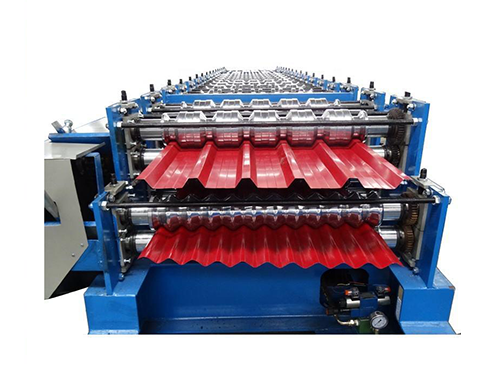

Double Layer Roll Forming Machine: Core Equipment for Roof Panel Production

Time:2026-01-04 09:50:17 Author:xiangyi Click:60

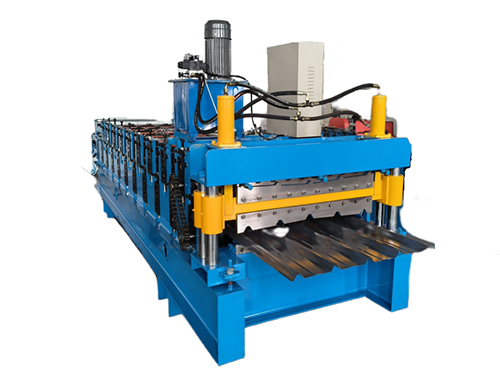

In the construction industry, roof panel production efficiency and quality directly affect project progress and building durability. Among the various equipment used in this field, the double layer roll forming machine stands out as core equipment, playing an irreplaceable role in optimizing production processes, reducing costs, and improving product performance. This article will explore the working principle, core advantages, application scenarios, and reasons for its status as a key device in roof panel production, helping you gain a comprehensive understanding of this essential construction machinery.First, it is necessary to clarify the basic definition and working principle of a double layer roll forming machine. Different from the traditional single-layer roll forming machine, this equipment is designed with two independent roll forming systems in one machine body, which can realize the simultaneous production of two different types or specifications of roof panels. Its working process is based on the continuous roll forming technology: the metal coil (usually galvanized steel coil, color steel coil, etc.) is uncoiled by the uncoiler, leveled by the leveling device to eliminate internal stress, and then sent to the two sets of roll forming rollers respectively. Under the continuous extrusion and bending of the rollers with precise shapes, the metal sheet is gradually formed into the preset roof panel profile, and finally cut into the required length by the automatic cutting device. The whole process is automated, with high continuity and stability, which fundamentally ensures the consistency of roof panel dimensions and shape accuracy.As the core equipment for roof panel production, the double layer roll forming machine has obvious advantages that traditional equipment cannot match. The most prominent advantage is the improvement of production efficiency. By integrating two production lines into one, the equipment can complete the production of two batches of roof panels in the same time and space, which is equivalent to doubling the production capacity without increasing the floor area. For construction material manufacturers with large order volumes, this can greatly shorten the delivery cycle and enhance market competitiveness. Secondly, it has excellent cost-saving performance. Compared with purchasing two single-layer roll forming machines, the double-layer model has lower one-time investment cost, and also saves the cost of workshop space, power consumption, and manual operation. A single operator can complete the monitoring and operation of the whole production process, which effectively reduces the labor cost.In addition, the double layer roll forming machine has strong versatility and flexibility. Through the replacement of roll forming rollers and the adjustment of control parameters, it can produce various types of roof panels, such as corrugated roof panels, trapezoidal roof panels, standing seam roof panels, etc., which can meet the different design requirements of industrial plants, commercial buildings, residential quarters, and other construction projects. At the same time, with the upgrading of technology, modern double layer roll forming machines are mostly equipped with CNC control systems, which can realize intelligent parameter setting, fault alarm, and production data statistics, reducing the error caused by manual operation and improving the overall production management level.

The application scenarios of the double layer roll forming machine cover almost all fields of roof panel production. In the production of prefabricated buildings, which is developing rapidly in recent years, this equipment has become a standard configuration because it can efficiently produce prefabricated roof panels that meet the assembly requirements, ensuring the rapid

construction of prefabricated buildings. In the construction of industrial plants, the double layer roll forming machine can produce large-area, high-strength roof panels, which have good wind resistance, waterproofness, and corrosion resistance, adapting to the harsh working environment of industrial plants. For commercial buildings and residential buildings, it can produce roof panels with beautiful appearance and diverse styles, meeting the aesthetic and functional needs of modern architecture. In addition, it is also widely used in the renovation of old buildings, temporary buildings, and other projects, providing high-quality roof panel materials for various construction scenarios.

Why can the double layer roll forming machine become the core equipment for roof panel production? In addition to the above advantages, it is also closely related to the development trend of the construction industry. With the continuous promotion of energy conservation, environmental protection, and efficient construction concepts, the construction industry has higher and higher requirements for building materials production equipment. The double layer roll forming machine adopts automated production, which reduces material waste and energyconsumption, in line with the concept of green production. At the same time, its high efficiency and high-precision production characteristics can meet the needs of large-scale and standardized construction in the modern construction industry, promoting the transformation and upgrading of the roof panel production industry.