- WEBSITE -

Current location: HOME > NEWS > Frequently Asked Questions >

Analysis of Functional Positioning and Key Technical Parameters of the Floor Bearing Plate Deck Forming Machine

Time:2025-12-04 04:53:12 Author:xiangyi Click:64

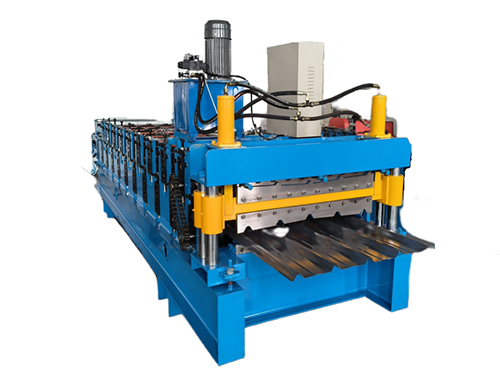

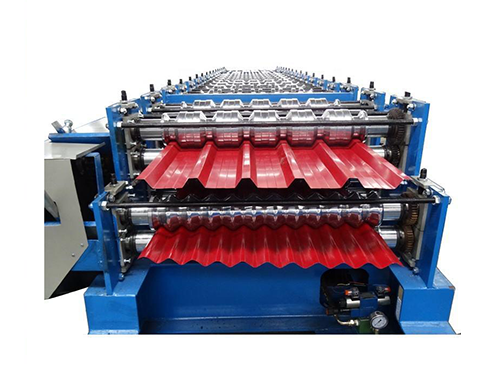

The floor bearing plate deck forming machine is a special-purpose equipment for producing floor bearing plates (steel bearing plates, architectural profiled steel sheets). Its core function is to process metal coils such as galvanized steel sheets into profiled plates with V-shaped, U-shaped, trapezoidal or other corrugated cross-sections through the roll bending and cold forming process. Such plates are mainly used as permanent formwork in the construction field, and can also be applied to other structural support scenarios. The following is an elaboration from three dimensions: equipment type, technical parameters, and application advantages:

I. Equipment Types and Functional Positioning

According to the shape of the formed cross-section and process requirements, floor bearing plate deck forming machines can be subdivided into multiple models:

750-type floor bearing plate forming machine: It produces steel bearing plates with high wave crests and high strength, featuring simple wave shapes and good adhesion. During installation, after laying and spot-welding the steel mesh, it is combined with on-site concrete pouring to form a high-strength floor slab structure.

1025-type floor bearing plate forming machine: Suitable for manufacturing 688-type floor slabs, the formed plates have higher load-bearing capacity and seismic performance, and are often used in high-rise steel structure buildings.

Closed-end floor bearing plate forming machine: It produces closed-end cross-section plates through a special roll forming process. For example, the YX48-200-600 type equipment has up to 36 forming passes, which can realize closed-end stitching of plates and improve waterproof performance and structural stability.

II. Analysis of Key Technical Parameters

Taking mainstream equipment as examples, its technical parameters reflect the equipment performance and processing accuracy:

Electronic control system: It adopts industrial computer PLC frequency conversion control to realize an automated production process and ensure stable forming accuracy. For instance, the main engine power of the 750-type equipment is 22 kW, the computer shearing power is 4 kW, and the working speed reaches 8-10 meters per minute.

Forming structure: The forming shafts of the whole machine are made of bearing steel CR12 with hard chrome plating, adopting a Φ80 solid shaft design, and are matched with 1.5-inch transmission chain sprockets to ensure wear resistance during long-term operation. The fuselage is made of 18mm medium plate and 350H steel frame to improve equipment rigidity.

Hydraulic system: The pressure of the hydraulic pump is set in the range of 10-12Mpa. Combined with the hydraulic shearing device, it achieves precise fixed-length cutting. The shearing blades are made of Cr12 material and undergo heat treatment with HRC58°-60° to ensure flat and burr-free cutting edges.

III. Core Advantages in Construction Applications

The plates produced by the floor bearing plate deck forming machine have significant advantages in the construction field:

Improved construction efficiency: As permanent formwork, it eliminates the installation and dismantling procedures of traditional formwork, shortening the construction period by more than 30%. For example, in high-rise buildings, it can realize the simultaneous laying of profiled steel sheets on multiple floors and the flow operation of layered concrete pouring.

Optimized structural performance: The wave crest design of the formed plates increases the bonding force with concrete. In the construction phase, it serves as continuous lateral support for steel beams, improving the overall stable load-bearing capacity; in the service phase, it acts as the bottom reinforcement of the floor slab, reducing the amount of steel bars by 15%-20%, while reducing the self-weight of the floor slab and correspondingly reducing the size of beams, columns and foundations.

Reduced comprehensive cost: By optimizing material usage and construction processes, the construction cost per square meter can be reduced by 8%-12%. For example, the floor bearing plate produced by the 750-type equipment reduces the engineering steel consumption by 10% and concrete consumption by 30% under the same load-bearing capacity.