- WEBSITE -

Current location: HOME > NEWS > Frequently Asked Questions >

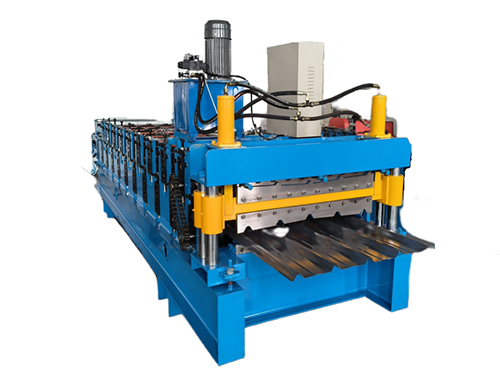

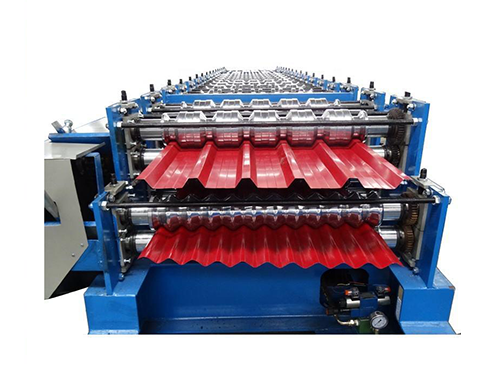

Installation and electrical precautions for tile press equipment

Time:2025-11-06 03:48:19 Author:xiangyi Click:60

Characteristics of tile press equipment: It has the advantages of operation, maintenance, upkeep, mechanical debugging, and easy mold replacement. The entire unit's automation control system adopts a highly integrated network and intelligent operation. This device adopts high-level automatic control software to achieve production information management. During the straightening process of the color plate produced by the tile press equipment, the profile will move from top to bottom, left to right, requiring a relatively loose gap between the straightening mechanism and the profile. There may be gaps between the straightening mechanism and the upper, lower, left, and right surfaces of the profile, with a gap size between 0.010-0.050in (0.25-1.25mm). If the straightening is twisted and deformed, the gap can be smaller.

The mold used for the tile press equipment requires one upper mold and six lower molds of the same specification size. First, install the upper mold and one lower mold. The lower mold is directly installed on the hexagonal wheel worktable, and the upper mold is installed on the bottom surface of the sliding seat, with an appropriate thickness of cushion plate placed to protect the upper and lower molds. After the molds are closed, the gaps around the four edges are uniform, and the distance between the upper and lower molds is equal to the thickness of the required tile blank. Then, based on the upper mold, the worktable is rotated and the remaining five lower molds are installed. Only after all the upper and lower molds are installed can the vehicle be driven to press the tiles. The manual placement and removal process of the tile press equipment: Before using the equipment, check whether the connections are secure, whether the installation bolts and nuts are tightened, and whether sufficient lubricating oil is added to the left and right chassis before starting the machine for testing. First, run the machine empty and carefully observe whether there is vibration, noise, whether the oil window is filled with oil, and whether the movements of various components are coordinated. Only then can the mold be installed. When installing the mold, cut off the power supply and manually move the motor belt or large gear to rotate the worktable and raise the sliding seat to a high point. Use an object to support it between the worktable and the bottom surface of the sliding seat, so that the sliding seat can fall naturally and cause an accident.

For the electrical precautions of the tile press machine:

1、 Electricians need to understand the type and performance of the workshop's wiring and equipment. Without a clear understanding of the equipment's performance, they cannot take risks in using it.

2、 Electricians need to set a time to check the condition of motors and electric control consoles. If they see any problems during the inspection, they should handle them at an appropriate speed. When checking the degree of the motor, first check that there is no power, and then check based on the back of the hand.

3、 Except for temporary construction work, temporary wires should not be installed, lights should not be hung randomly, tools and welding equipment should use stable sockets, and previous wires should not be changed arbitrarily.

4、 According to the regulations, his products should be inspected and cared for on schedule, and unused electrical product circuits should be dismantled.