- WEBSITE -

Current location: HOME > NEWS > Frequently Asked Questions >

Core Features and Application Scenarios of CZ Purlin Roll Forming Machine

Time:2025-12-04 04:54:19 Author:xiangyi Click:163

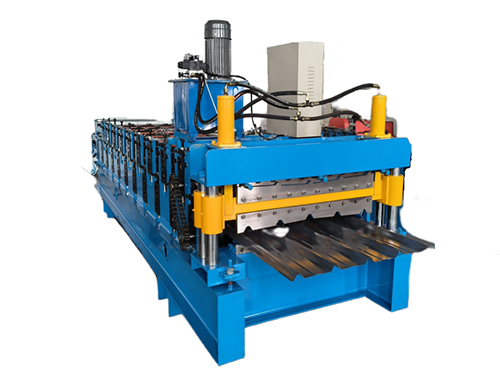

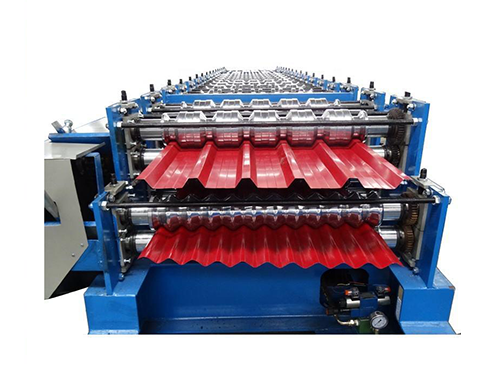

The CZ purlin roll forming machine is a kind of cold roll forming equipment that integrates the functions of a C-section steel machine and a Z-section steel machine. It realizes the rapid switch production of C and Z type purlins through PLC system control, featuring high efficiency, precision and flexibility, and is widely used in the field of building steel structures. The following is a detailed description of its core features, technical parameters, application scenarios and industry advantages:

I. Core Features

Two-in-one FunctionIntegrates the production capacity of C-section steel and Z-section steel, enabling continuous processing of two cross-sectional shapes with the same set of equipment without replacing forming rolls or molds, which significantly saves investment costs and site space.

Automated ControlAdopts a PLC (Programmable Logic Controller) and touch screen human-machine interaction system, supporting functions such as parameter presetting, automatic punching, and fixed-length cutting. The production process is highly automated, reducing manual intervention.

Rapid Model ChangeoverSome models support completing C/Z steel specification switching within 3 minutes. A stepless adjustment system (such as hydraulic motor drive) is used to achieve millimeter-level adjustment of web and flange dimensions, adapting to the needs of multi-specification orders.

High-Precision FormingThe number of forming passes is usually 16-24. The rolls are made of Cr12 or GCr15 alloy steel and undergo vacuum heat treatment (hardness HRC58-62) to ensure wear resistance during long-term operation. Some equipment is equipped with a coaxial design to reduce the risk of shaft breakage and improve forming stability.

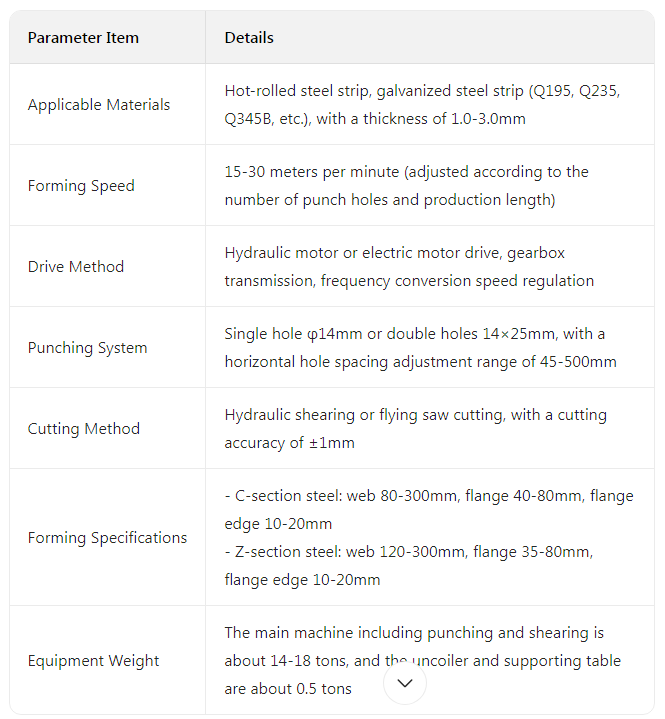

II. Technical Parameters (Taking a Typical Model as an Example)

III. Application Scenarios

Building Steel Structures

Main Structure: Used as roof purlins and wall beams for industrial plants, warehouses, and commercial buildings, replacing traditional concrete or wood, reducing the structural self-weight by more than 30%.

Floor Bearing Plate Support: Cooperates with profiled steel plates to form a composite floor system, improving construction efficiency.

Infrastructure

Bridge Construction: Used to manufacture bridge decks, support structures and guardrails, with strong corrosion resistance and a service life of more than 35 years.

Pipeline Supports: Provides lightweight and high-strength support solutions for air conditioning, fire protection and other systems.

Industrial Equipment

Shelf Systems: Produces components such as columns and beams to meet the load-bearing requirements of automated warehouses.

Electrical Cabinet Frames: Processes high-precision profiles to ensure the stability of equipment installation.

IV. Industry Advantages

Cost Optimization

Saves Mold Costs: No need to open separate molds for different specifications, reducing initial investment.

Reduces Downtime: The rapid model changeover function allows the production line to continuously handle multi-specification orders, improving equipment utilization.

Quality Improvement

High-Precision Processing: Automated control ensures consistent forming dimensions and reduces manual errors.

High Material Utilization: The cold bending process reduces the waste of leftover materials, saving 10%-15% of steel compared with the hot rolling process.

Environmental Protection and Energy Saving

Low Energy Consumption Design: The hydraulic system power is optimized (such as 30KW air-cooled motor), and combined with frequency conversion speed regulation technology to reduce operating energy consumption.

Long-Life Components: Key components such as rolls and gearboxes are specially treated, extending the maintenance cycle to more than 5 years.

V. Typical Cases

A Steel Structure Plant Project: The CZ steel all-in-one machine was used to produce Z-type purlins (web 200mm, flange 60mm), with a daily output of 20 tons, meeting the construction needs of a 30,000-square-meter plant and shortening the construction period by 20% compared with traditional processes.

A Logistics Center Shelf System: Through the rapid switching function of the equipment, C-section steel columns (web 150mm) and Z-section steel beams (web 180mm) were produced synchronously, realizing integrated processing of the shelf system.