- WEBSITE -

Current location: HOME > NEWS > Frequently Asked Questions >

Composition, Working Principle and Performance Characteristics of Rolling Shutter Door Forming Machine

Time:2025-12-04 04:58:09 Author:xiangyi Click:178

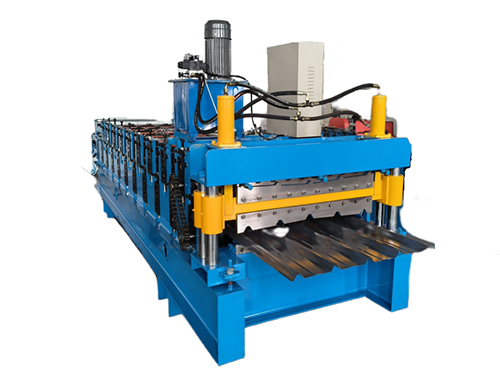

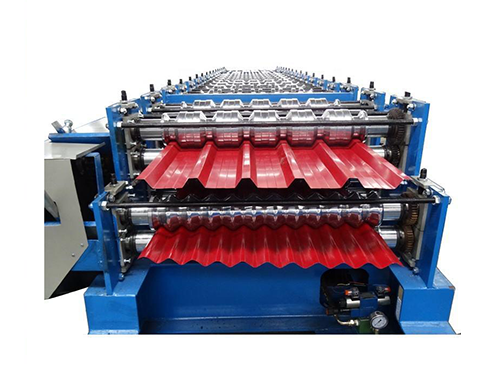

The rolling shutter door forming machine is a special-purpose equipment for producing rolling shutter door slats. It converts metal coils into door slats with specific cross-sectional shapes through a continuous roll forming process, and is widely used in the construction decoration, industrial manufacturing, and security industries. The following is a detailed introduction to the rolling shutter door forming machine:

I. Equipment Composition and Working Principle

The rolling shutter door forming machine is mainly composed of the following parts:

Feeding and Guiding Platform: Guides metal coils into the main forming machine.

Main Forming Machine: Realizes progressive plastic deformation of metal strips through multi-station roller sets to form door slats with reinforcing ribs, lock structures, and decorative lines.

Forming and Shearing Device: Adopts hydraulic shearing or flying saw cutting to ensure a cutting accuracy of ±1mm.

Hydraulic Station: Provides the power required for the operation of the equipment.

Computer Control System: Adopts industrial computer PLC control to realize automated production, supporting functions such as parameter presetting, automatic punching, and fixed-length cutting.

Edge Locking Machine: Used in conjunction with the forming machine to complete the edge locking process of door slats.

II. Technical Parameters and Performance Characteristics

Processing Capacity

Material Thickness: 0.3-2.0mm, suitable for different materials such as galvanized steel sheets, color-coated steel sheets, and aluminum sheets.

Processing Width: 200-1000mm, meeting the production needs of door slats of different specifications.

Forming Speed: 6-15m/min, and some models can reach 10000mm/min.

Main Motor Power: 2.2-30kW, with three-phase asynchronous motors of different powers configured according to the model.

Forming Accuracy

The servo control system achieves a forming accuracy of ±0.1mm, ensuring that the matching tolerance between the door body and the guide rail meets standards.

Some high-end models are equipped with a laser online detection system, which monitors dimensional deviations in real time, automatically compensates for roller gaps, and the straightness error does not exceed 0.5mm per linear meter.

Structure and Durability

Roller Material: 45# steel or Cr12 alloy steel, treated with vacuum heat treatment (hardness HRC58-62), featuring strong wear resistance.

Transmission System: Chain transmission or gearbox transmission, and some models adopt a stepless adjustment system to reduce the risk of shaft breakage.

Lubrication System: Centralized oil supply device that delivers grease to each bearing position regularly and quantitatively to extend the service life of the equipment.

Energy Conservation and Environmental Protection

Adopts a servo motor drive system, which saves more than 35% energy compared with traditional hydraulic drive and meets the first-level energy efficiency standard.

The waste recycling system is integrated at the equipment outlet, increasing the material utilization rate to more than 98.5%.

III. Application Scenarios and Advantages

Construction Field

Commercial Complexes: Produces fire-resistant rolling shutter doors that meet the GB14102-2005 Fire Resistant Rolling Shutters standard, with a door body thickness of 0.4-1.5mm.

Underground Garages: Produces wind-resistant rolling shutter doors, and the door slat cross-section adopts a multi-cavity structure with a wind resistance rating of over level 12.

Logistics Warehouses: Produces high-strength rolling shutter doors that adapt to frequent opening and closing needs and reduce maintenance costs.

Industrial Manufacturing

Factory Facilities: Produces industrial doors, and cooperates with prestressed roll forming devices to improve the rigidity and durability of the door body.

Equipment Supporting: Provides customized rolling shutter door solutions for cold chain, chemical, and other industries.

Security Industry

Anti-theft Rolling Shutter Doors: Through specially designed interlocking roll forming molds, a continuous occlusal structure is formed, meeting the RC3 level requirements in the EN1627-2011 anti-theft door rating standard.

IV. Market Trends and Purchase Suggestions

Intelligent Upgrading

Some new models integrate IoT modules, which can be connected to the factory MES system through the Industry 4.0 interface to realize real-time monitoring of production data and historical traceability.

The flexible production system supports a single device to process multiple door type orders, reducing the minimum economic batch to 50 linear meters.

Purchase Suggestions

Brand and Reputation: Choose manufacturers with strong technical strength and perfect after-sales service, such as Foshan Texin Machinery Equipment Co., Ltd.

Cost-Effectiveness: Select the appropriate model according to the production scale and demand, and avoid blindly pursuing high-end configurations.

On-Site Inspection: Ask the manufacturer to provide samples or on-site demonstrations to inspect the forming effect, operation stability, and operational convenience.