- WEBSITE -

Current location: HOME > NEWS > Industry Trends >

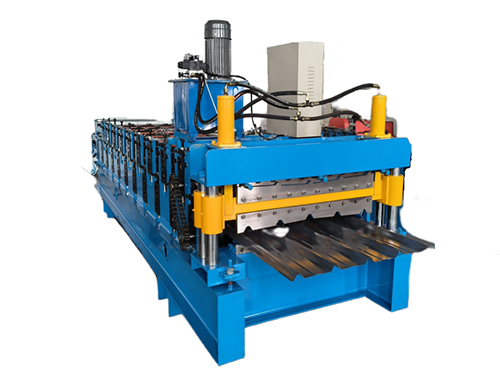

How to check whether the high-speed guardrail molding machine meets the standard?

Time:2025-12-29 10:55:03 Author:xiangyi Click:102

Checking whether the high-speed guardrail molding machine meets the standards can be promoted from the following core dimensions to ensure equipment performance, product quality and safety compliance:

I. Verification of Basic Qualification and Design Standard

Check the qualification documents such as equipment certificate and production license, and confirm that the manufacturer has the corresponding production qualification, the equipment model and parameters are consistent with the design drawings, and meet the basic requirements of national/industrial standards such as GB/T 31439.1-2015 (Corrugated Beam Steel Guardrails Part 1: Two Corrugated Beam Steel Guardrails) for molding equipment.

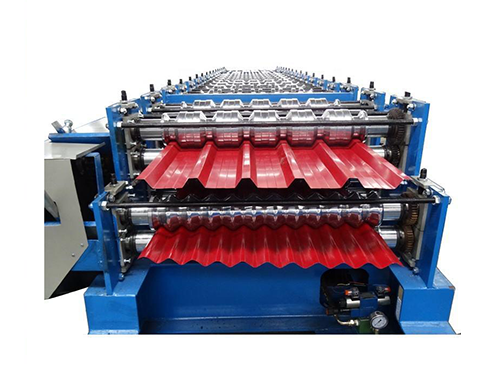

Check the structural design of the equipment: whether the welding quality of the frame (no cracks and air holes), the transmission system (precision of gears, chains and other parts) and the layout of the forming roller system are reasonable, and whether they meet the forming process requirements of the guardrail plate (such as 4320mm×310mm×85mm specifications).

II. the molding accuracy and product quality check

Sampling in trial production: use equipment to process standard guardrail blanks, and test the key dimensions of finished products, including wave height, wave distance, plate thickness deviation and total length accuracy, which must meet the tolerance range specified in the standard (for example, wave height is 85 mm 2 mm).

Appearance quality inspection: the surface of the finished product is free from wrinkles, scratches and deformation, and the weld (if any) is smooth and free from defects; Check the flatness of the plate with flatness detection tools to ensure that there is no obvious warping.

Verification of mechanical properties: sampling the trial-produced finished products, testing the yield strength, tensile strength and other indicators, which need to match the mechanical properties of the original materials, and there is no excessive plastic deformation affecting the structural strength after molding.

III. Verification of Equipment Operation Performance

No-load running test: start the equipment to run without load, and check the running stability of the transmission system (no abnormal noise and vibration), the motor load and speed meet the design parameters, and the hydraulic/pneumatic system has no leakage.

Load running test: continuously process a batch of blanks at the rated production speed, check the stability of the equipment, the deviation between the molding speed and the design value is ≤ 5%, the pressure of the roller system is uniform, and there is no material jam or car jam.

Verification of automation and control system: If the equipment has the functions of automatic feeding and cutting, the positioning accuracy and action coordination are tested, the control system responds in time, and the alarm devices (such as overload and material jam alarm) are sensitive and effective.

IV. Verification of Safety and Environmental Protection Standards

Safety protection: the protective covers of the rotating parts of the equipment (roller system and chain) are complete and firm, and the emergency stop button, leakage protection and other safety devices are effective; The electrical system is reliably grounded, which conforms to GB 5226.1-2019 (Mechanical and electrical safety Part 1: General technical conditions).

Environmental protection requirements: Dust and noise emissions in the production process should meet the national standards (such as noise ≤85dB (A)). If there is a cooling and lubrication system, it is necessary to have a waste liquid recovery device to avoid pollution.